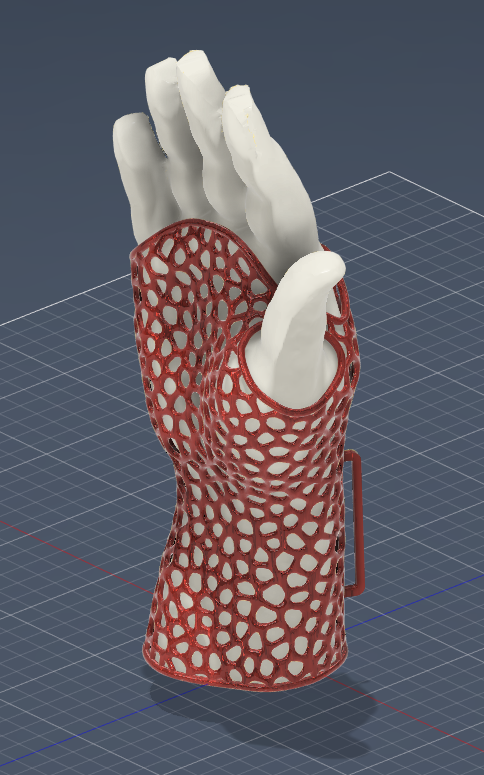

Custom 3D Printed Wrist Brace

At the beginning of the year, I found myself experiencing persistent wrist tendonitis that caused so much pain that my daily life was getting negatively affected. My usual go-to in these cases would be an off-the-shelf brace from the pharmacy, but I soon found out that these braces actually made my pain worse because they were designed for carpel tunnel and therefore had the support in the wrong areas. I knew I could better, and I had the tools to make it happen.

I started with getting a 3D scan of my hand and wrist using the LiDAR scanner on my iPad, then I imported the mesh into Autodesk Fusion. Creating the base shape of the brace around the wrist mesh was accomplished by first using the Form tool to create a cylindrical form, then the Pull tool to draw the form to the contours of the mesh. I made sure to create clearances for my thumb and other fingers, and once I was happy with the overall shape, I thickened the form and saved it as a fine STL mesh. That mesh was then put into the voronator tool to create a Voronoi pattern that would allow for better airflow and reduce the amount of filament used in printing while also retaining structural stability. The tool, however, does not create outlines for the structure, so I brought the generated model back into Fusion and used the pipe tool to create a rounded border around all the edges to further increase structural stability and comfort. Finally, I added attachment points for an elastic velcro strap and an opening to slip my hand in. And with that, I was ready to get printing!

I created the first draft print in PLA to test the fit and function, as it's inexpensive and easy to print with. I printed it in a vertical orientation with tree supports to support the larger overhangs in the Voronoi pattern and around the thumb hole. My first print revealed that I needed an opening along the entire length of the brace to allow for easier on and off, and also that I needed to use PETG as my filament, as it has excellent layer adhesion and can flex much more than PLA without breaking. The PETG print functioned extremely well when paired with a fingerless compression glove which added an additional layer of comfort and stability.

Takeaways:

- Using 3D scanning, Fusion, and Voronator, I was able to create a custom-fitted brace that was both comfortable and extremely supportive

- This workflow helps further democratize access to custom medical support devices, which many cannot access for financial reasons

- PLA is great for prototypes, but PETG is much more durable for functional use cases where flexibility is necessary