3D Printing on Fabric Experiments

3D printing has evolved rapidly over the last decade, going from largely only the world of professional industrial prototyping and manufacturing to a widely accessible fabrication resource and art form. This wide accessibility has allowed people of all experience levels to bring their ideas to the real world and has arguably become an art form in its own right.

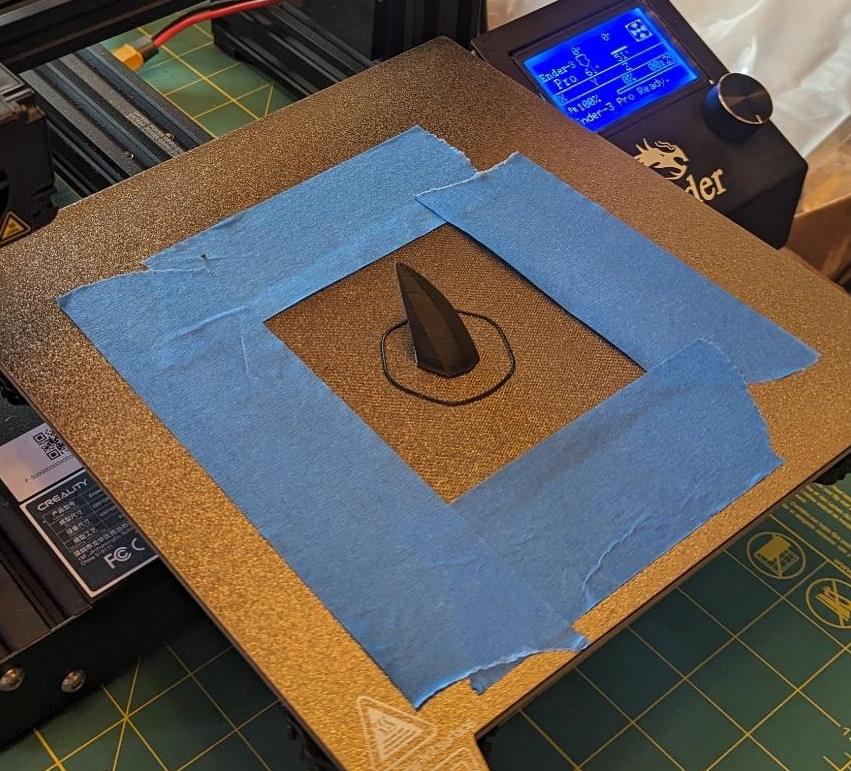

One of the most interesting uses of 3D printing I've been working with is 3D printing directly onto fabric. I had first come across this concept online, in the form of 3D printed dragon scales on tulle fabric. The process works by having the printer put down a few layers of filament, pausing the print, adding a mesh fabric on top of the print bed, securing it down (usually with tape or magnets), and then continuing the print. The melted plastic that is subsequently extruded by the printer encapsulates the mesh, permanently bonding the two together. Utilizing this basic principle, a whole host of options begin to open up. Entirely 3D printed "fabrics" have been circulating around the internet for years now, but often times they lack the flexibility and drape that is able to be achieved by using mesh fabric as the substrate for the 3d printed elements.

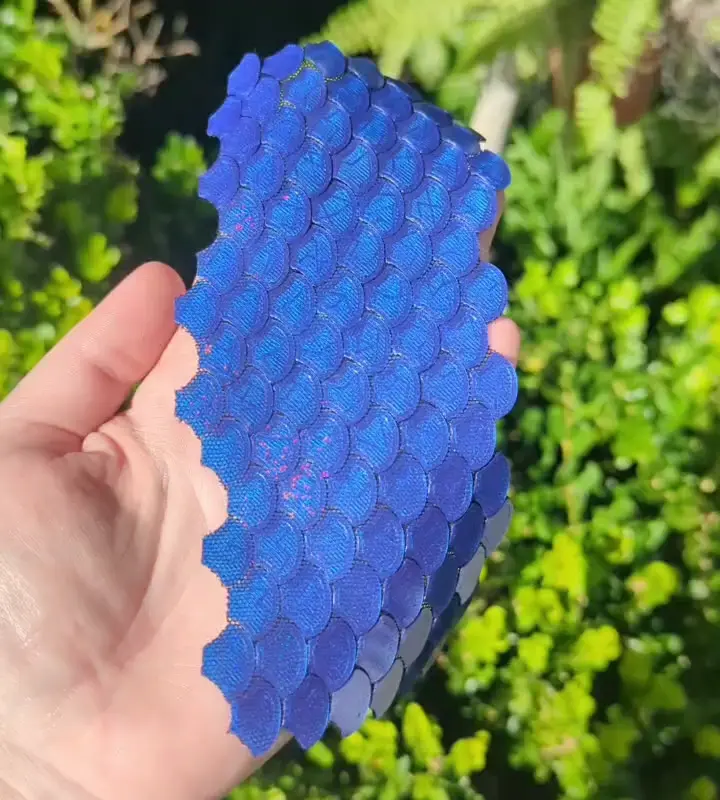

In my experiments, I first started with the classic tulle and dragon scales popularized by Shorey Designs , then tried my hand at a mermaid/fish scale pattern in a translucent PLA, which I found I could punch holes into after the fact ant turn into a gauntlet. With these proof-of-concepts nailed down, I started to push further by making my own designs, changing up the fabric, and taking advantage of the holographic build plates that allow the first layer to have a sparkle and shine that's directly embedded into the first layer of the print.

I had begun with printing on tulle because that seemed to be the tried-and-true material that others had had success using, but realized quickly that it was quite fragile and tore easily, which didn't suit my needs for items that could handle being worn. Digging through my local Jo-Ann's, I found a 4-way stretch mesh, which is typically used for athletic wear, and gave it a try. The openness of the mesh allowed the plastic to bond just as well as with the tulle, but with the added benefit of being quite durable and tear-resistant. This is my go-to fabric of choice now, but I have found that any fabric that can withstand the melted plastic temperatures and that has an open enough structure to allow the plastic to bond through the fabric would be a viable option.

As for filaments, I especially like using materials that have a glow, sparkle, or multi-color qualities. Tri-color filaments are especially fun as they "change color" depending on the direction they're laid down in by the printer. And if you're good with a flat surface of your fabric print, printing on a holographic plate can add a variety of visually intriguing patterns that glitter in the sunlight. TPU is also a great option if you want your fabric print to retain as much flexibility as possible.

Experimenting with this technique has opened up my eyes to a new world of possibilities for wearable tech and 3d printed textiles, and I'm excited for the chance to create a wearable that integrates both 3d printed as well as lighting elements that will push the edges of what's possible in fashion tech and tell a story through the garment as well.

Key Takeaways:

- Choosing the right fabric based on both the aesthetic as well as functional needs of the project is key. Do some test prints before committing.

- Same goes for the filament. Need flexibility? TPU. Have smaller "tiles" and want fun color? Tri-color PLA. Sparkles? Holo build plate. Hotel? Trivago.

- Make sure to add a pause in your slicer after the 2nd/3rd layer, and secure the fabric down with clips or magnets so it doesn't get bunched up when the print head travels over it (and make sure the magnets are placed in a way that they don't catch on the nozzle when the printer resumes the print!)